Is sausage-making an art? Is it science? Or both? There has been debate about that in the meat and poultry processing industry for a long time.

The smaller side of the industry tends to see sausage-making as an art, with scientific aspects playing a necessary but lesser role. The industry’s large side views science as a major aspect, with the art of sausage-making not quite as critical. Skip Cart

A long time ago – several thousand years ago – sausage was developed as a way of preserving meat. Salt was used as the only known meat preservative. But over time, that changed, with the sausage containing not only salt, but many other ingredients far beyond that simple way of preserving meat.

In fact, there have been great strides in virtually all parts of sausage production. These improvements include more control over the shape of the sausage and a big expansion of the animal species and ingredients used in sausage production, beyond pork to poultry, vegetables, seafood, and other items. The types of casings that hold the sausage meat together go beyond only natural casings. But perhaps the biggest advancement is in the equipment and machines that are used to make sausage, due in part to the revolution in technology that affects how sausage is made.

“It’s true, the basis for starting to make sausage was to preserve the meat,” said Brian Krumsee, western regional sales manager for Handtmann Inc. in Lake Forest, Ill. “A lot of sausage-making began with meat with salt added to preserve it, inside a sheep natural casing. Now, there are synthetic casings and plastic casings. Alginate casing, a seaweed derivative, is used in making plant-based and other non-meat-based sausage. The synergies that exist between meat and non-meat fillings make it easy for processors and sausage-makers to make virtually any kind of sausage.”

Whatever casing is employed to hold the meat or other filling, there are numerous styles of sausage, Krumsee explained. “Fresh sausage is made from meats that aren’t smoked or cured, like a bratwurst, a fresh pork sausage or even a Polish sausage. Cured sausage could be either dried or cooked. Dry sausage could be pepperoni or salami. Cooked sausage could be smoked, then cooked.”

But Krumsee said there are changes in appetite for types of sausages as well, even on a geographical basis. In the middle of the country, he says, the taste is still for meat sausages, whether pork, chicken, or beef. “On the ‘coasts,’ (the East Coast and the West Coast), there is increasing interest in plant-based sausage, even from cultured meats,” Krumsee said.

Eventually, though, all sausage goes through the stuffer or filler.

“Sausage stuffing is the encasement of a meat or PBP batter into a casing or wrapper of some kind, to either keep it in a certain shape, to keep it from spoiling, give it a certain bite or texture when it is cooked, smoked or dehydrated,” said Stefan Neumann, a meat specialist and master butcher for Reiser, a manufacturer of sausage stuffers and other meat processing equipment, based in Canton, Mass.

“The casing allows the meat processor making the sausage to portion each link, to process and package large quantities of fresh and ready-to-eat sausages for sale. It also gives the consumer an easy way to cook or reheat the meat,” he said.

But sausage often begins with fat and lean trimmings that go into a blender, mixer, or grinder. Spices are added, as well. That is before stuffing takes place. “We are at the front end,” said Dwayne Lee, sales manager for FPEC Corp., in Springdale, Ark. “The equipment we sell blends, mixes, and grinds the meat. It creates the meat block that is eventually delivered to the stuffer.”

All sausage stuffer makers, including Reiser, sell vacuum-assisted stuffers for small, medium, and large meat and poultry plants. The stuffers are available with either a positive displacement double screw or a vane cell pumping system. All the stuffers are complemented by a range of inline grinders, linkers, link cutters, hanging systems and link loaders for automated linking to packaging.

“Our newest technology includes the Vemag CC25 alginate sausage line. It is a continuous coextrusion system that produces sausages in edible alginate casings,” said Neumann. “Alginate casings are a cost-effective alternative to more expensive natural and collagen casings and can significantly reduce labor and sausage production costs.”

He said vacuum-assisted Vemag stuffers are a big step forward in technology because accurate portion control is assured.

“It is easier for customers to have a net weight package and less giveaway, which adds to the customer’s bottom line. Compared to most piston stuffers, that have no integrated linking device, we can also twist link the sausages or communicate with a clipper that is downstream from the Vemag,” Neumann explained.

Handtmann’s meat processing tools and equipment are a “full line solution, from raw materials to packaging, including vacuum stuffers and fillers, Krumsee said.

The company’s emphasis is on custom solutions for processors’ needs for production and it offers a four-model high vacuum filler series, each designed for a specific product category. The HVF 658 is for salami, the HVF 660 works well with cooked sausage, HVF 664 is a powerful ham machine and HVF 770 works well with whole muscle products. The models include Handtmann’s vane cell system so processors can reduce residual air in dried sausage, eliminate voids in whole muscle products, and increase shelf life while communicating “artisan quality” to consumers. Vane cells rotate, so the sausage product is pushed out.

“As far as new technology goes, our biggest move in this area is full-line solutions – tools and equipment for sausage makers and other meat processors, including grinding, mixing, forming and conveying,” Krumsee said. That includes OEM (original equipment manufacturer) service, walking plant operators through troubleshooting if there is a problem, with no travel necessary.

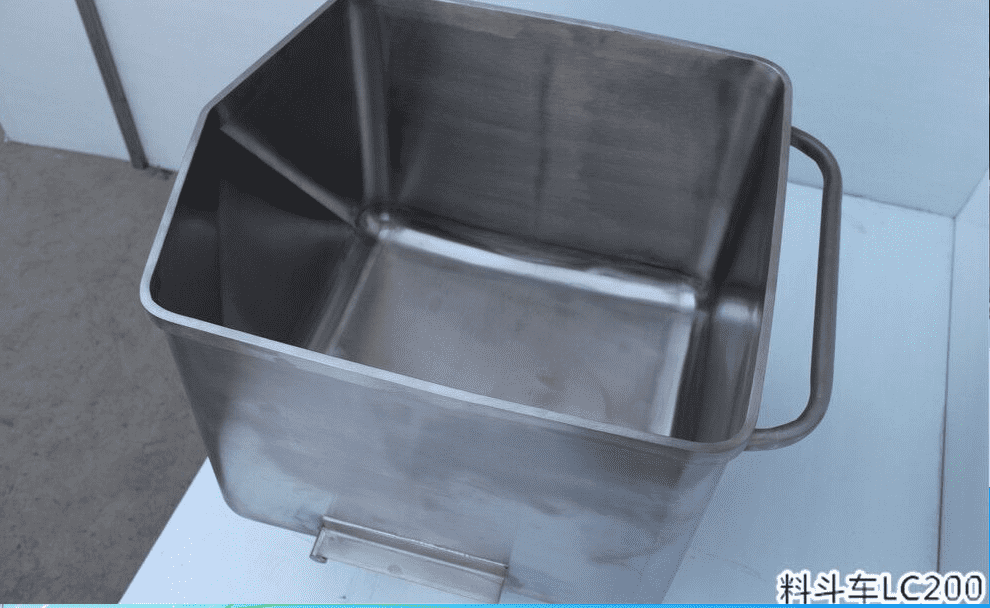

Doug Vogelsmeier, product line manager for Marlen, a global manufacturer of food processing equipment and systems, based in Riverside, Mo., said his company has an entire series of machines that can be used for stuffing and pumping. The company’s OPTI series of vacuum stuffing and pumping machines feature twin piston pumping systems with a variety of hoppers designed to match the sausage maker’s product requirements.

“Where the Marlen pumps excel is product that requires gentle handling, high vacuum, or are abrasive.

“The company offers meat processing tools for large and small meat processors, but most of the Marlen pumps are for larger-volume processors,” Vogelsmeier said.

The stuffers and pumps in the OPTI series are available in multiple capacities ranging from 10,000 to 34,000 lbs per hour production rates.

“Sausage-making is an art, and from the pump end, there is really no new technology. The true artisans who make sausage use tried-and-proven processes, which is what we at Marlen offer,” Vogelsmeier explained.

There is no doubt that automation has become a serious issue affecting meat and poultry processors, as well as virtually all American industries.

According to Neumann, Reiser’s technology adds a high degree of automation and production efficiency to sausage production lines.

Krumsee, Neumann and Lee agree that the sausage-making tools, including stuffers and fillers, are being created and moved ahead as part of the industry advancement to automating production lines, including automation controls like hands-free options. They cite the industry difficulty in finding enough workers, complicated by the immigration challenges the United States and other countries face. They also agree that the job of suppliers is to provide efficient and cost-effective ways for meat and poultry processors to make their products.

“The equipment and tools we make, including sausage stuffers and fillers, help the industry to create their products, despite the labor shortages and immigration challenges,” Handtmann’s Krumsee pointed out.

At the same time, Handtmann, Reiser and FPEC Corp. officials think the small and very small poultry and meat processors are an important part of the industry in the United States, Canada, and other countries, and build tools and equipment specifically for that segment of the industry.

“The family-owned businesses have a true passion for meat processing and are always open to help from us,” Krumsee noted.

The tool and equipment suppliers agree that the advancing technology has made it easier in some ways for sausages to be produced. Plant workers can be put to work on the tools and machines, and a good product will be turned out. They also believe that an important development in sausage-making is the ability to link sausage fillers and other tools together on the line so sausage products can be created with no separation from upstream or downstream manufacturing activities. This results in more products made faster.

“There are a lot of different processes that go into making sausages,” FPEC’s Lee noted. “Different equipment must be set up to make different products. The tools and systems are purposely designed, and there are many ways to set it up, depending on the amount of room and layout of the plant. We design, build and set up everything for the processors, and service the equipment. Plants rely on us to do this.”

Smoke House For Sausage Processing Sausage stuffers that are operating under the latest technology allow sausage-makers to accomplish four major goals important to the sausage industry: create a net weight package, portioning (controlling the portions of product they are making), allow less free giveaway, and most importantly, treat the consumer fairly.