Exploring the use of high-density polyethylene (HDPE) in mining equipment.

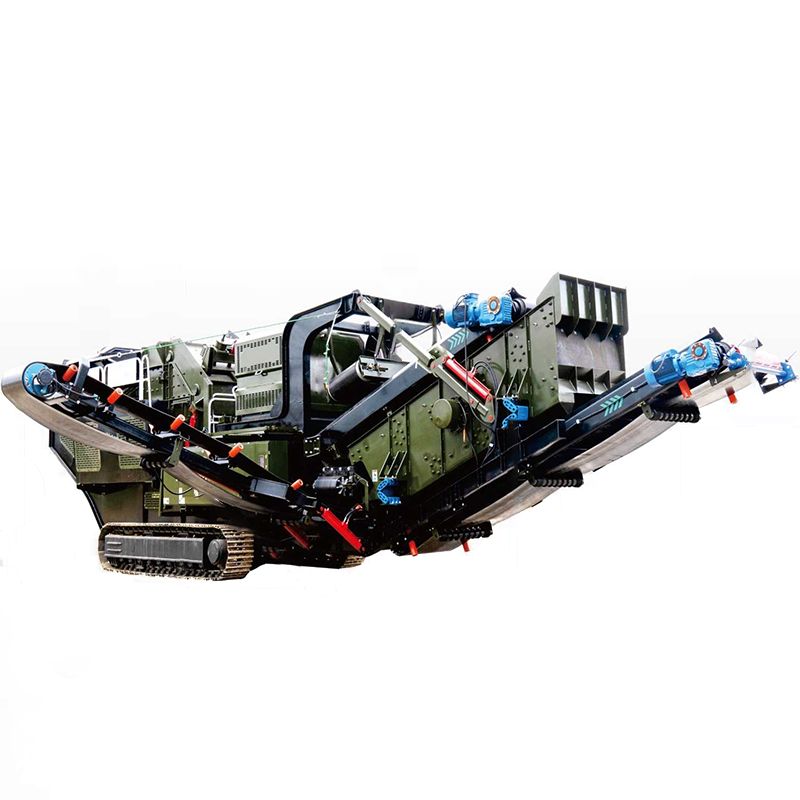

Mining is an essential industry that provides valuable resources for various sectors worldwide. With the increasing demand for materials, improving the efficiency and sustainability of mining equipment has become paramount. High-density polyethylene (HDPE) has emerged as a revolutionary material in manufacturing mining equipment, offering numerous benefits in terms of durability, flexibility, cost-effectiveness, and environmental impact. tracked impact crushing station

This article delves into the role of HDPE in mining equipment, highlighting its advantages, applications, and more.

The mining industry demands equipment capable of enduring challenging conditions, making it essential for such equipment to withstand extreme wear and tear. By incorporating HDPE into the manufacturing process of mining equipment, companies can ensure dependable performance, longevity, and resilience against the rigors of the industry.

This, in turn, enables mining operations to run smoothly, cost-effectively, and with reduced downtime. Companies are also able to enjoy safer and more efficient mining operations. Using HDPE to manufacture critical mining equipment leads to a more reliable and robust infrastructure that operators can rely on.

While various materials are available for manufacturing mining equipment, HDPE stands out due to its durability and strength, flexibility and versatility, and cost-effectiveness. If you’re a business in the mining industry, understanding why each of these factors is critical when choosing a material for your mining equipment is critical.

Mining equipment is designed to operate in challenging environments, often encountering abrasive materials, high temperatures, heavy loads, and other extreme conditions. It’s essential for the equipment to be durable and strong to withstand these stresses and prevent frequent breakdowns. A highly durable material, like HDPE, ensures that the mining equipment remains operational for extended periods, improving productivity and reducing the need for constant repairs or replacements. It’s impact, corrosion, and wear-resistant, making it a highly durable solution.

Mining operations often require equipment to adapt to varying conditions, such as extreme cold and hot temperatures, fluctuating loads, and changing operational requirements. HDPE is a material that offers flexibility and versatility and can be used to manufacture equipment that can withstand a wide range of conditions and applications. This adaptability makes it easier for mining companies to operate efficiently and safely in diverse environments, reducing the need for specialised equipment for each unique situation.

The mining industry is highly competitive, with companies striving to minimise operational costs while maximising productivity. Choosing cost-effective materials for manufacturing mining equipment, like HDPE, can significantly reduce overall costs in several ways. The material’s durability and resistance to wear and corrosion lead to lower maintenance costs and longer service life. Also, its lightweight nature and ease of installation and maintenance reduce downtime, save costs, and enhance productivity.

HDPE’s versatile properties make it suitable for various mining equipment applications, ranging from critical piping for moving liquid material to containers for moving heavy material from mines to sorting areas. Examples of applications include: pipes and fittings: conveyor belts; liners and covers; tanks and containers; railcars and trucks; plus gears, sheaves, gaskets, and other parts. The environmental benefits of HDPE in mining equipment mean that it not only enhances performance but also contributes to a more sustainable mining industry.

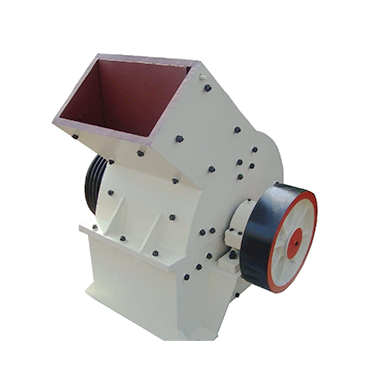

Jaw Crusher Eccentric Shaft © Setform Limited 2019-2024 | Privacy policy | Archive