Most of us are content to get our semiconductors from the usual sources, happily abstracting away the complexity locked within those little epoxy blobs. But eventually, you might get the itch to roll your own semiconductors, in which case you’ll need to start gearing up. And one of the first tools you’ll need is likely to be something like this DIY tube furnace.

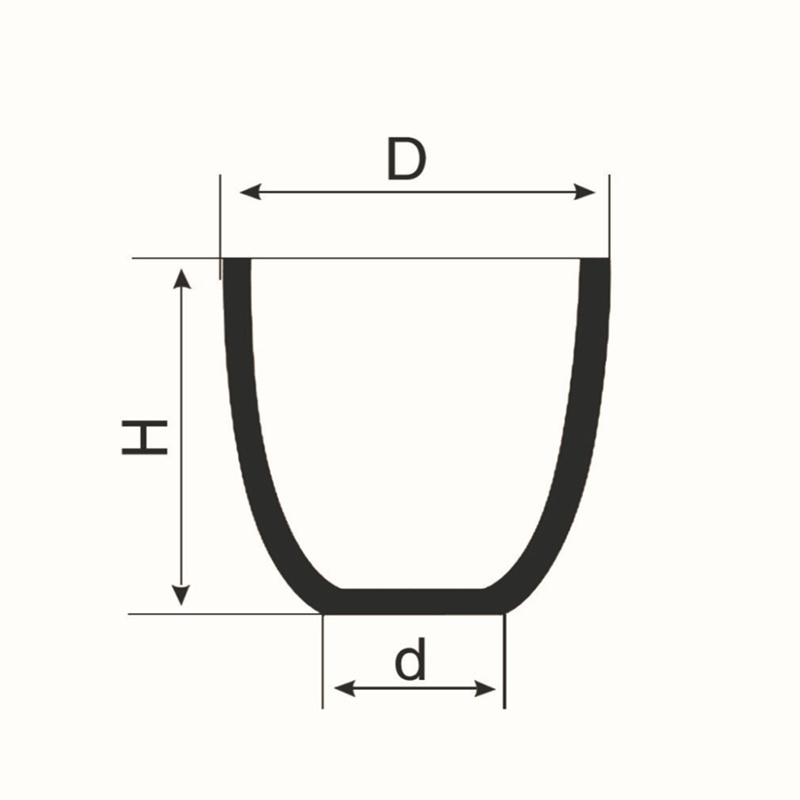

For the uninitiated, [ProjectsInFlight] helpfully explains in the video below just what a tube furnace is and why you’d need one to start working with semiconductors. Perhaps unsurprisingly, a tube furnace is just a tube that gets really, really hot — like 1,200° C. In addition to the extreme heat, commercial furnaces are often set up to seal off the ends of the tube to create specific conditions within, such as an inert gas atmosphere or even a vacuum. The combination of heat and atmospheric control allows the budding fabricator to transform silicon wafers using chemical and physical processes. Silver Casting Crucible

[ProjectsInFlight]’s tube furnace started with a length of heat-resistant quartz glass tubing and a small tub of sodium silicate refractory cement, from the plumbing section of any home store. The tube was given a thin coat of cement and dried in a low oven before wrapping it with nichrome wire. The wrapped tube got another, thicker layer of silicate cement and an insulating wrap of alumina ceramic wool before applying power to cure everything at 1,000° C. The cured tube then went into a custom-built sheet steel enclosure with plenty of extra insulation, along with an Arduino and a solid-state relay to control the furnace. The video below concludes with testing the furnace by growing a silicon dioxide coating on a scrap of silicon wafer. This was helped along by the injection of a few whisps of water vapor while ramping the furnace temperature up, and the results are easily visible.

[ProjectsInFlight] still needs to add seals to the tube to control the atmosphere in there, an upgrade we’ll be on the lookout for. It’s already a great start, although it might take a while to catch up to our friend [Sam Zeloof].

Continue reading “Start Your Semiconductor Fab With This DIY Tube Furnace” →

Depending on the chef’s skill, many exciting things can happen in the kitchen. Few, however, grab as much immediate attention as when a piece of foil or a fork accidentally (?) makes it into the microwave oven. That usually makes for a dramatic light show, accompanied by admonishment about being foolish enough to let metal anywhere near the appliance. So what’s the deal with this metal-melting microwave?

As it turns out, with the proper accessories, a standard microwave makes a dandy forge. Within limits, anyway. According to [Denny], who appears to have spent a lot of time optimizing his process, the key is not so much the microwave itself, but the crucible and its heat-retaining chamber. The latter is made from layers of ceramic insulating blanket material, of the type used to line kilns and furnaces. Wrapped around a 3D printed form and held together with many layers of Kapton tape, the ceramic is carefully shaped and given a surface finish of kiln wash.

While the ceramic chamber’s job is to hold in heat, the crucible is really the business end of the forge. Made of silicon carbide, the crucible absorbs the microwave energy and transduces it into radiant heat — and a lot of it. [Denny] shares several methods of mixing silicon carbide grit with sodium silicate solution, also known as water glass, as well as a couple of ways of forming the crucible, including some clever printed molds.

As for results, [Denny] has tried melting all the usual home forge metals, like aluminum and copper. He has also done brass, stainless steel, and even cast iron, albeit in small quantities. His setup is somewhat complicated — certainly more complex than the usual propane-powered forge we’ve seen plenty of examples of — but it may be more suitable for people with limited access to a space suitable for lighting up a more traditional forge. We’re not sure we’d do it in the kitchen, but it’s still a nice skill to keep in mind.

Continue reading “Radio Waves Bring The Heat With This Microwave-Powered Forge” →

For some mobile projects like small carts or rolling cabinets, your standard casters from Harbor Freight will do just fine. But some projects need big, beefy wheels, and these custom cast aluminum wheels certainly make a statement. Mostly, “Watch your toes!”

To be honest, [Brian Oltrogge]’s wheels are an accessory in search of a project, and won’t be crushing feet anytime soon. He made them just to make them, but we have no beef with that. They’ve got a great look that hearkens back to a time when heavy metal meant something else entirely, and things were made to last. Of course, being cast from aluminum sort of works against that, but there are practical limits to what can be done in the home foundry. [Brian] started with a session of CAD witchcraft followed by machining the cores for his molds. Rather than doing this as lost foam or PLA, he milled the cores from poplar wood. His sand mix is a cut above what we usually see in home-brew sand casting — sodium silicate sand that can be cured with carbon dioxide. All his careful preparation meant the pour went off without a hitch, and the wheels look great.

We’ve featured quite a few metal casting projects recently, some that went well and some that didn’t. [Brian] looks like he knows what he’s doing, and we appreciate the workmanship that he puts on display here.

Continue reading “Custom Aluminum Wheels Teach A Thing Or Two About Casting” →

Building a car engine can be a labor of love. Making everything perfect in terms of both performance and appearance is part engineering and part artistry. Setting your creation apart from the crowd is important, and what better way to make it your own than by casting your own parts from old beer cans?

[kingkongslie] has been collecting parts for a dune buggy build, apparently using the classic VW Beetle platform as a starting point. The air-cooled engine of a Bug likes to breathe, so [kingkongslie] decided to sand-cast a custom crankcase breather from aluminum.

Casting solid parts is a neat trick but hardly new; we’ve covered the techniques for casting plastic, pewter, and even soap. The complexity of this project comes from the fact that the part needs to be hollow. [kingkongslie] managed this with a core made of play sand and sodium silicate from radiator stop-leak solution hardened with a shot of carbon dioxide. Sure, it looks like a Rice Krispie treat, but a core like that will stand up to the molten aluminum while becoming weak enough to easily remove later. The whole complex mold was assembled, beer cans melted in an impromptu charcoal and hair-dryer foundry, and after one false start, a shiny new custom part emerged from the sand.

We’ve got to hand it to [kingkongslie] – this was a nice piece of work that resulted in a great looking part. But what we love about this is not only all the cool casting techniques that were demonstrated but also the minimalist approach to everything. We can all do stuff like this, and we probably should.

Continue reading “Custom Engine Parts From A Backyard Foundry” →

Steel Melting Crucible By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Learn more