Latest Dimensional Metrology, Inspection and Quality News

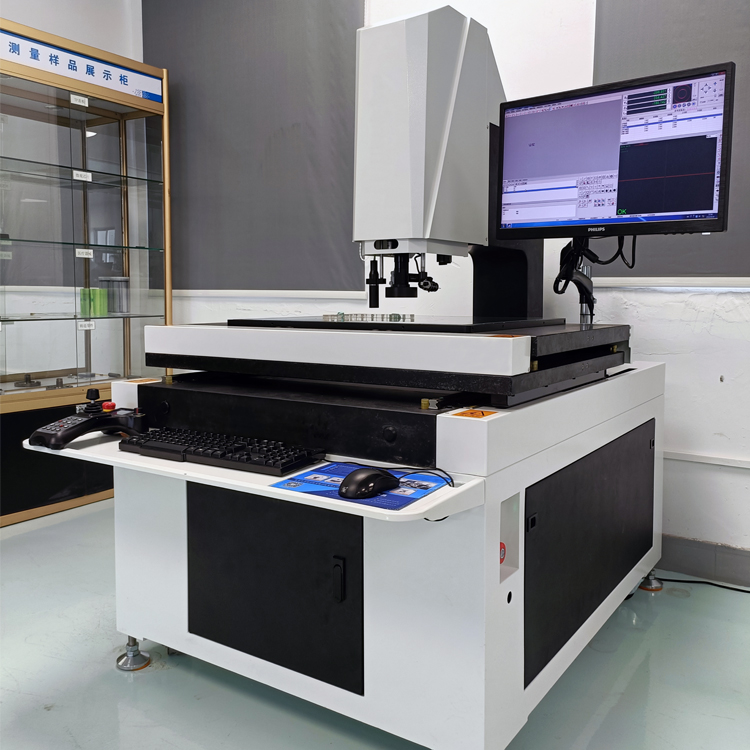

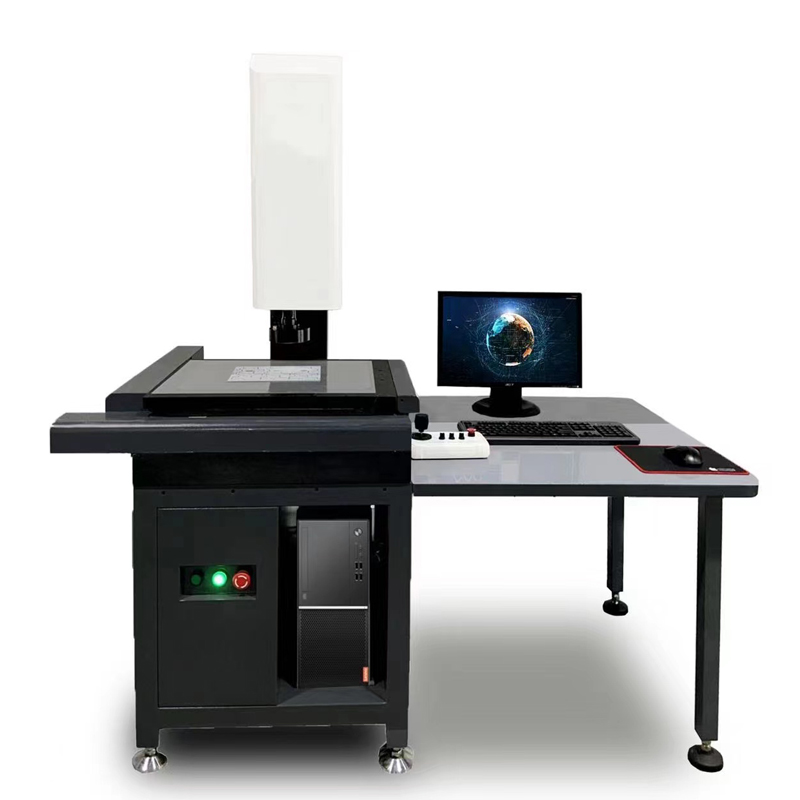

Pair Eyewear is an American eyewear company that produces unique and customisable glasses and frames. Pair eyewear is all about making a very dull medical device, something exciting and interesting and unique every day. Video Measurement Machine

Scott Craycraft the company’s Director of Quality explains “Being able to automate production processes is the best way to maintain and increase production capacity over time. Here in Irvine we make customised eyewear and tops, customers can have the choice to wear whatever they want. Our objective here is to produce as many as 4000 pairs every single day and that requires us to have automation and storage that is world class. To achieve successful on shoring of eyewear and manufacturing automation is critical. Fast, rapid, movement through the processes is extremely important.”

“The installed Metrios measuring system was a godsend to us because it allowed us to very basically reduce the amount of time it took to measure an individual part when we’re doing incoming inspection by at least 90%. One of the things that is great about the Metrios is that the user interface makes it real intuitive, it’s simple to operate, it’s very easy to program, and it yields precise results, which is critical”

Automation is Key to Producing 4,000 Pairs of Glasses a Day

While human interaction within Pair Eyewear’s production processes is still a key element, there is a need to invest more and more in automation. For this reason, the company chose the Metrios measuring system, which allows fast and error-proof incoming checks:

“Using conveyor systems, intelligent automation, we’re able to get 300 frames per hour through our systems up to 4000 frames a day in this 14,000 square foot production facility. So in Irvine here we have a complete optical lab with surfacing and edging and hard coating and thin film coating. So no manufacturing process would be complete without some element of the human interaction to get the customer exactly what they need. Each of the items is custom fit, so when the lenses go in, everything is adjusted to make sure that the fit is perfect and finishes out our platform.”

Tight Tolerances Are Extremely Important

Pair Eyewear has 750,000 tops coming through the facility currently which will grow to over 2,000,000 when the company is at full production. “Automation in measurement is critical to just being efficient and being good stewards of the resources that we’ve been given.”

Video Measuring Machine Price For more information: www.metrios.com